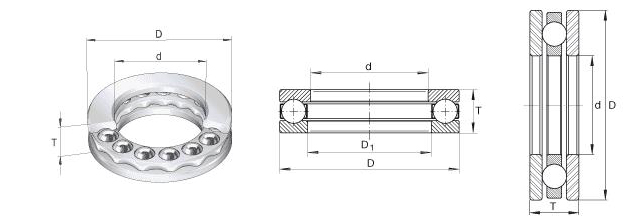

Thrust ball bearing

Inquiry now: Thrust ball bearings are designed to withstand thrust loads during high-speed operation, and are composed of washer-shaped ferrules with ball rolling raceway grooves. Because the ferrule is in the shape of a cushion, thrust ball bearings are divided into ...

Thrust ball bearings are designed to withstand thrust loads during high-speed operation, and are composed of washer-shaped ferrules with ball rolling raceway grooves. Because the ferrule is in the shape of a cushion, thrust ball bearings are divided into two types: flat base cushion type and self-aligning spherical cushion type. In addition, this kind of bearing can bear axial load, but cannot bear radial load.

According to the force, it is divided into one-way thrust ball bearings and two-way thrust ball bearings. The one-way thrust ball bearing can bear one-way axial load, and the two-way thrust ball bearing can bear the two-way axial load, in which the shaft ring and the shaft are matched. The mounting surface of the seat ring is a spherical bearing with self-aligning performance, which can reduce the influence of installation errors. Thrust ball bearings cannot bear radial load, and the limit speed is low.

Features

1. There are two types, one-way and two-way;

2. In order to allow installation errors, whether it is one-way or two-way, you can choose the spherical self-aligning spherical seat cushion type or the spherical seat ring type;

3. High-quality steel-use ultra-clean steel that can extend the life of the bearing by 80%;

4. High-level grease technology-can extend the life of the grease and improve the performance of the bearing;

5. High-grade steel ball-quiet and smooth when rotating at high speed;

6. With the ferrule in the option, installation errors can be tolerated.

Thrust ball bearings are only suitable for parts that bear one side of the axial load and low speed, such as crane hooks, vertical water pumps, vertical centrifuges, jacks, low-speed reducers, etc. The shaft ring, seat ring and rolling element of the bearing are separated and can be assembled and disassembled separately.