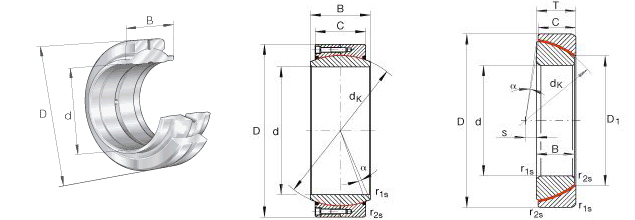

Needle roller bearings are roller bearings with cylindrical rollers. Relative to its diameter, the rollers are both thin and long. This type of roller is called a needle roller. Although the bearing has a small cross-section, the bearing still has a high load bearing capacity. The needle roller bearing is equipped with thin and long rollers, so the radial structure is compact, and its inner diameter and load capacity are the same as other types of bearings. Small, especially suitable for supporting structures with restricted radial installation dimensions.

According to different applications, bearings without inner ring or needle roller and cage components can be selected. At this time, the journal surface and shell hole surface matching the bearing are directly used as the inner and outer rolling surfaces of the bearing to ensure the load capacity and running performance Same as the bearing with ring, the hardness, machining accuracy and surface quality of the raceway surface of the shaft or housing hole should be similar to the raceway of the bearing ring. This kind of bearing can only bear radial load.

According to different applications, bearings without inner ring or needle roller and cage components can be selected. At this time, the journal surface and shell hole surface matching the bearing are directly used as the inner and outer rolling surfaces of the bearing to ensure the load capacity and running performance Same as the bearing with ring, the hardness, machining accuracy and surface quality of the raceway surface of the shaft or housing hole should be similar to the raceway of the bearing ring. This kind of bearing can only bear radial load.

Needle roller bearings have large carrying capacity and are suitable for supporting structures with restricted installation dimensions. The journal surface is hardened as the rolling surface. The bearing is fitted into the seat hole with a press fit, eliminating the need for axial positioning.