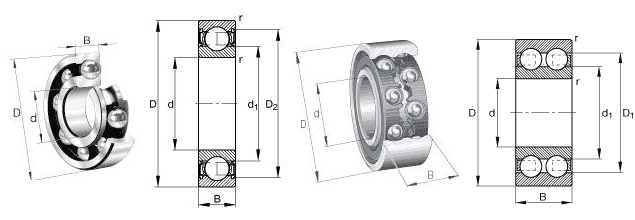

Deep

groove ball is a relatively common type in rolling bearings. The basic

deep groove ball bearing consists of an outer ring, an inner ring, a set

of steel balls and a set of cages. There are two types of deep groove

ball bearings, single row and double row. The deep groove ball structure

is divided into two types: sealed and open. The open type means that

the bearing does not have a sealed structure. The sealed deep groove

ball is divided into dust-proof and oil-proof. Sealing, dust-proof seal

cover material is stamped steel plate, which only serves to prevent dust

from entering the bearing raceway. The oil-proof type is a contact oil

seal, which can effectively prevent the grease in the bearing from

overflowing.

The single row deep groove ball bearing type code is 6,

and the double row deep groove ball bearing type code is 4. Its

structure is simple and easy to use. It is a universally produced and

widely used type of bearing. The deep groove ball bearing mainly bears

radial load, and can also bear radial load and axial load at the same

time. When it only bears radial load, the contact angle is zero. When

the deep groove ball bearing has a large radial clearance, it has the

performance of an angular contact bearing and can bear a large axial

load. The friction coefficient of the deep groove ball bearing is very

small and the limit speed is also high.

Deep groove ball bearings

have a simple structure and are easy to achieve higher manufacturing

accuracy compared to other types. Therefore, they are easy to produce in

series and have lower manufacturing costs, and they are extremely

common. In addition to the basic type, deep groove ball bearings also

have various modified structures, such as: deep groove ball bearings

with dust cover, deep groove ball bearings with rubber seals, deep

groove ball bearings with stop grooves, and Deep groove ball bearing

with large load capacity with ball gap, double row deep groove ball

bearing.

Deep groove ball bearings are the most representative

rolling bearings. They have a wide range of applications and are

suitable for high-speed or even extremely high-speed operation. They are

also very durable and do not require frequent maintenance. This type of

bearing has low friction coefficient, high limit speed, low

manufacturing cost, and easy to achieve high manufacturing accuracy. The

size range and form are varied, and they are used in industries such as

precision instruments, low-noise motors, automobiles, motorcycles and

general machinery. They are a type of bearing widely used in the

machinery industry.